ES-Biax18 biaxial geotechnical centrifuge shaker

|

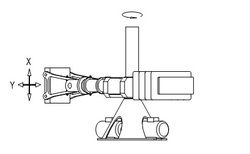

Directions of shaking for ES-18 Biax Shaker when mounted on centrifuge.

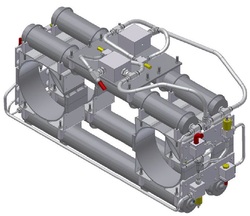

On-arm hydraulic distribution and control system

|

Description

To provide the highest possible performance within the available space and weight limitations of the centrifuge, the shaker actuators and slip table are integrated into a dedicated shaker centrifuge platform, incorporating - three independent high performance Team servohydraulic actuators for ultra-high frequency response. Each actuator incorporates two integrated hydrostatic spherical pad bearings to provide extremely rigid axial coupling to the slip-table while also providing a nearly frictionless transverse and rotational interface. - a low-mass, high-stiffness aluminum alloy slip table supported by 16 elastomeric pad bearings designed for high vertical stiffness and with very low horizontal stiffness - low-friction fluoropolymer-lined spherical bearings utilized at the platform hinge supports to faciltate free swing-up of the shaker platform - high flexibility, high pressure hydraulic supply hoses for superior reliability and long life - an integral sump tank and hyrdaulically-driven scavenge pump for reliable collection and return of hydrostatic bearing bypass oil to the HPS at high g-levels - integrated mounts for optional attachment of accessories such as PVL's CRM-4 in-flight robotic manipulator, loading devices such as PVL's LF-2 hydraulic load frame, camera systems, etc. - includes an instrumentation shelf for placement of data acquisition and control hardware. The shaker platform is designed to be interchangeable with the original centrifuge platform and can be easily installed or removed from the centrifuge by making or breaking the hydraulic and electrical connections and subsequently following the centrifuge manufacturer’s procedure for installation and removal of the platform. A complete turnkey system includes the shaker platform, a hydraulic power supply with a sequential pump controller (typically located in a utility room adjacent to the centrifuge enclosure), a hydraulic distribution and control system (mounted on the centrifuge arm), two PVL SC-2000 servo-controllers, two PVL PA-2000 power amplifiers, one PVL XC-2000 expansion chassis, one small-footprint industrial PC server with DAC interface board, and PVL’s high performance software for shaker control. Optional accessories - multi-port fluid rotary union for supply of high-presure hydraulic oil, compressed air, water - optical rotary union for high-speed data transfer - electrical rotary union to provide electrical power for on-arm instrumentation - on-arm equipment rack for convenient and secure mounting of instrumentation near the centrifuge axis of rotation |

Specifications

Shaking type 2 prototype horizontal directions

Shaking frequency 20-350 Hz

Peak dynamic force 49 kN (11000 lb)

Operating Range Up to 100g centrifugal acceleration

Peak velocity 1 m/sec (40 inch/sec)

Peak displacement (each axis) 12 mm (0.5 inch)

Maximum payload mass 250 kg (550 lbm)

Maximum payload dimensions 1000 mm x 660 mm x 800 mm

Accommodates rigid-walled or 1D and 2D laminar-box model containers

Shaking type 2 prototype horizontal directions

Shaking frequency 20-350 Hz

Peak dynamic force 49 kN (11000 lb)

Operating Range Up to 100g centrifugal acceleration

Peak velocity 1 m/sec (40 inch/sec)

Peak displacement (each axis) 12 mm (0.5 inch)

Maximum payload mass 250 kg (550 lbm)

Maximum payload dimensions 1000 mm x 660 mm x 800 mm

Accommodates rigid-walled or 1D and 2D laminar-box model containers

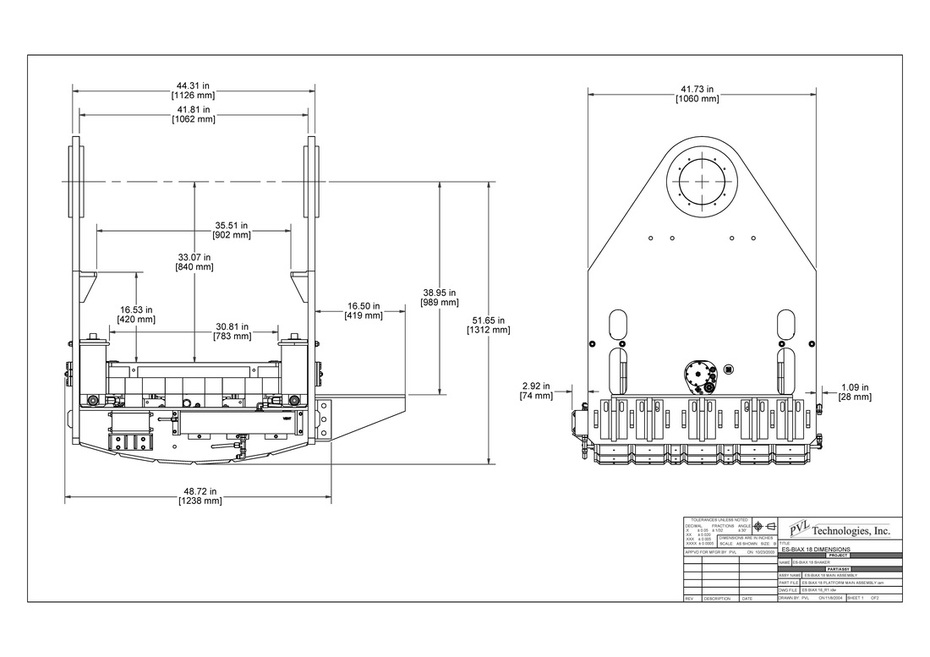

Overall dimensions of ES-Biax 18 shaker platform

Specifications are subject to change without notice.