CORE TUBES, CATCHERS AND NOSES

The VC 3.5.2 vibracore can be used with plastic, aluminum, and steel core tubes. Field crews, over the years, have found various configurations of core tubes, liners, and core catchers to be effective in collecting sediment core samples. There is no correct method and will depend upon preference, trial and error, sediment type, project budgets as well as core tube materials that can be sourced locally.

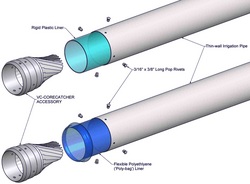

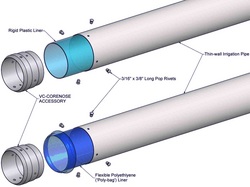

Generally, plastic rigid core tubes will be used alone or with a plastic core catcher attached. Core samples collected this way are normally retained in the plastic core tube after collection. Metal core tubes can be either expendable (thin wall irrigation without a liner) or reusable (with a thin wall plastic or poly bag liner). Reusable metal core tubes using a liner will require a metal core catcher or core nose to retain the liner (see descriptions below). A core nose allows entry of the sample without disturbance. A core catcher will aid in retention of the sample but cause some mixing as the sediments enter the tube.

We can provide you with some guidelines from client recommendations over the years.

Generally, plastic rigid core tubes will be used alone or with a plastic core catcher attached. Core samples collected this way are normally retained in the plastic core tube after collection. Metal core tubes can be either expendable (thin wall irrigation without a liner) or reusable (with a thin wall plastic or poly bag liner). Reusable metal core tubes using a liner will require a metal core catcher or core nose to retain the liner (see descriptions below). A core nose allows entry of the sample without disturbance. A core catcher will aid in retention of the sample but cause some mixing as the sediments enter the tube.

We can provide you with some guidelines from client recommendations over the years.

Livorno Harbor, Italy

PLASTIC CORE TUBES

Plastic core tubes, undoubtedly, have the benefit of being clear so the sediments can be visually inspected through the core length without removal from the tubes. Plastics are lighter, and can be easily cut to length with pipe cutters or saws. Plastic caps are readily available in many diameters also to cap off samples once they are collected. Plastic core tubes also offer the benefit of using plastic core catchers, which are easily constructible, economic and can be fastened to the core tube with pop rivets or glue. Lexan (polycarbonate) is a readily available core tube material that can be sourced though plastics companies. Ain Plastics http://www.ainplastics.comweeblylink_new_window ( a division of ThyssenKrup Materials) has been a known supplier. Pricing depends upon the material, diameter, wall thickness, length of core tube and number of linear feet. It is always advisable to identify a couple of suppliers early in a project and discuss your needs and their lead times in providing tubing. Generally, for 3.00” and 4.00” OD plastic core tubes, a 1/8” (0.125”) wall thickness is recommended. A thinner wall thickness may work fine for some applications. Suppliers may be willing to provide sample tubes, prior to an order being placed. www.caplugs.com is a good source for plastic caps to use as end caps on the core tubes. Additional ductape will keep the sample intact in the tube.

Poly bag liner being extracted

METAL CORE TUBES

Metal core tubes are generally either steel or aluminum, and can be used with or without plastic liners. Steel core tubes have the disadvantage of being heavy, especially in a 4.00”OD size. Wall thickness of aluminum and steel tubes are in the range of 0.050” – 0.125”. Steel tubes are generally used for shorter core samples up to about a maximum length of an 8’ core tube, with the VC 3.5 .2 vibracore.. Again, variations of this are also possible. Aluminum tubes offer some benefit in not being as heavy to manage. Both can be used with plastic liners, such as thin wall polycarbonate, or poly tubing that comes in long rolls with a 6-8 mil thickness. www.packingsupplies.com carry 6 mil poly tubing in 1000' rolls, 7" wide, part # L6T76 (for use with 4.00" OD core tubes). A handy website for metal tube is http://www.onlinemetals.comweeblylink_new_window.

For example, a 3.00”OD 316SS welded tube, 0.065” wall thickness, in an 8’ length is approximately $200/8’ section and weighs 2.1 lbs/ft. A 3.00”OD Aluminum 6061 T6 in a 0.065” wall thickness is roughly $140/8’ section and weighs 0.7lbs/ft. A 4.00”OD Aluminum runs about $245/8’section. (pricing averages from various websites as of March 2011)

Aluminum “irrigation” thinwall core tubes can also be used and offer either a convenient reuse core tube with liner for soft sediments or a disposable, (similar to rigid plastic) core tube. These are normally sourced from agricultural supply companies locally. Wall thicknesses vary from 0.050” – 0.072. http://www.hastingsirrigation.com is a website with information and specifications for this type of core tube. They are a large manufacturer with nationwide distribution.

It goes without saying that many options exist for the user. We can recommend, based upon client feedback, that Lexan (polycarbonate) is often the most feasible core tube since it offers many benefits. Metal is a better transmitter of vibration and may provide optimal penetration. Metal core noses and core catchers are more cumbersome to use but may be necessary for certain sediment conditions. It is recommended that owners and users of vibracore equipment spend time trying different configurations in order to develop their vibracoring skills. With repeated use, the user will become more and more familiar with the VC 3.5.2 vibracore capabilities and what types of core tubes and core catchers are best suited for the types of materials to be sampled.

We have standardized the use of aluminum tube (0.125" wall, 4.00"OD) and (0.050" wall, 4.00"OD) with the 7" , 6mil polytube and have core noses, and core catchers to fit these applications in stock. We will also manufacture to your specs.