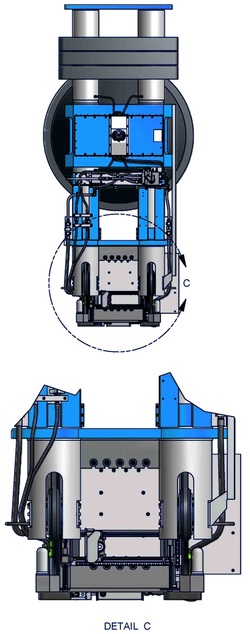

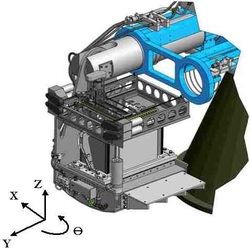

CRM-4 four-axis robotic manipulator

|

|

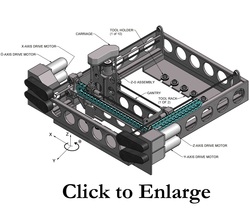

PVL’s CRM-4 is the next generation of robotic manipulator for geotechnical centrifuge testing. Developed after consultation with centrifuge users having extensive experience with first-generation robotic manipulators, the CRM-4 incorporates a number of important design and performance enhancements aimed at addressing limitations of the existing technology, including:

- providing significantly larger travel in all axes:

- higher load capacities:

- a more compact design, providing a clear and largely unobstructed view of

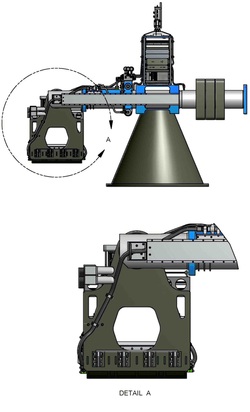

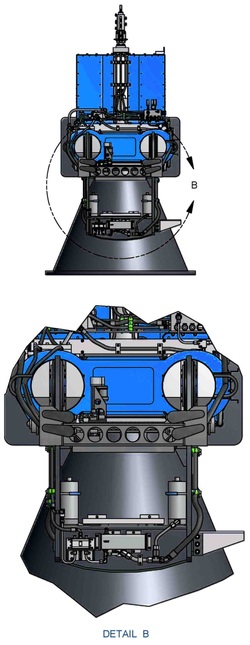

the work area; - an increase in tool storage from 4 tools to 10 tools; - an intuitive and efficient operator interface; - capability for operation together with PVL’s ultra-high performance ES-18A centrifuge shaker system and LB-2814 laminar box model container for conducting sophisticated dynamic model tests. Traditionally, single-purpose actuator systems have been used with geotechnical centrifuges to perform specific tasks while in-flight such as applying loads to model structures, inserting piles, depositing and excavating soil, grouting, soil contouring and profiling, and use of penetrometers to characterize soil properties in-flight. Due to weight and space limitations, such single-purpose actuators were typically mutually exclusive and could not be used in combination during a single test. More recently, multi-axis in-flight robotic manipulators with interchangeable tools have been developed to permit greater flexibility and enhanced modeling capabilities. These ‘first-generation’ robotic systems have indeed proven to be useful, but over time several practical limitations have become apparent: - first-generation robots tend to place large and heavy components directly over the centrifuge model container, obscuring the model surface from the view of cameras used for in-flight video monitoring and recording, and limiting the (Z-axis) payload capacity;

- because the design places a great deal of equipment on the moving gantry, first-generation robots tend to require a significant amount of overhead clearance and provide limited vertical (Z-axis) displacement capability; - in spite of their large size, the load capacity of first-generation robots is quite limited because of inefficient load distribution; - first-generation robots typically permit use of up to only four interchangeable tools per test, which has proven to be limiting in certain circumstances. In principal, robotic technology is ideal for repetitive sequential modeling activities such as incremental application of surcharge loads, insertion of individual piles to construct pile groups, placement of arrays of structures to provide soil reinforcement at multiple locations, etc. For activities such as these, where consumable elements (model foundations, piles, soil nails, geotextiles, etc.) are sequentially inserted or applied to the soil model, the required consumables must be cached in such a way that they can be easily accessed by the robot while in-flight. First-generation robots place the burden of designing the cache and programming the robot to access it on the user, a time-consuming and error-prone task; - first-generation robots utilize standard robotic tool holders which are large in size, limiting the number of tools that can be cached in the limited space available on the centrifuge arm. In spite of their large size, standard robotic tool holders tend to be relatively weak, limiting the forces that can be applied to the tool. The CRM-4 system is designed to address the limitations of the existing technology described above. To the greatest extent possible, all mechanical hardware is located at the periphery of the robot. This has several important advantages: - keeping the mechanical assemblies at the periphery permit a clear and largely unobstructed view of the work area, which is vitally important to permit use of multiple cameras to observe and record the operations; - minimizing the hardware in the space-critical region above the model container permits greater vertical (Z-axis) displacement; - by minimizing the dead load carried by the gantry and carriage, these structural members can accommodate higher applied loads while still meeting the robot’s positional accuracy specifications and overall weight requirements; - the CRM-4 provides caching of up to 10 tools and/or consumable elements in its integrated storage rack, and because these locations are pre-defined within the control software, storage and retrieval is fully automatic, requiring no additional programming; - the CRM-4 uses tool holders designed specifically for the severe centrifuge environment, providing high strength and rigid connections in a very compact space. Features of the CRM-4 system include: - Four displacement-controlled degrees of freedom - X, Y, Z, Θ - Operation at up to 100g centrifugal acceleration - Specially designed high capacity tool changer with 6 electrical lines rated at 5A, two fluid ports compatible with air, water and oil rated at 36 bar, and two fluid ports compatible with water and oil rated at 130 bar - Two tool racks to cache up to 10 tools/consumables - Digital servo-controllers for each axis - Portable control console consisting of a laptop computer with wireless network communications for programming ‘at the robot’ - An industrial PC server with digital interface board mounted on the centrifuge and connected to a wireless hub for control of the robot’s digital servo-controllers - Intuitive, easy to learn ROBCOS control software - Sealed motors to prevent damage from windblown soil particles and moisture - Includes a ‘starter toolkit’ consisting of 4 tools: one each of a laser displacement sensor for surface profile measurement, a Piezocone 3 cone penetrometer ,a gripper tool to grab and move small parts around the model, including capability for pushing model piles into the ground, and a fluid injector to penetrate the soil and inject fluids at different depths. |

CRM-4 Specifications

|

|

| ||||||||||||||||||||||||||||||||||||||||||||||

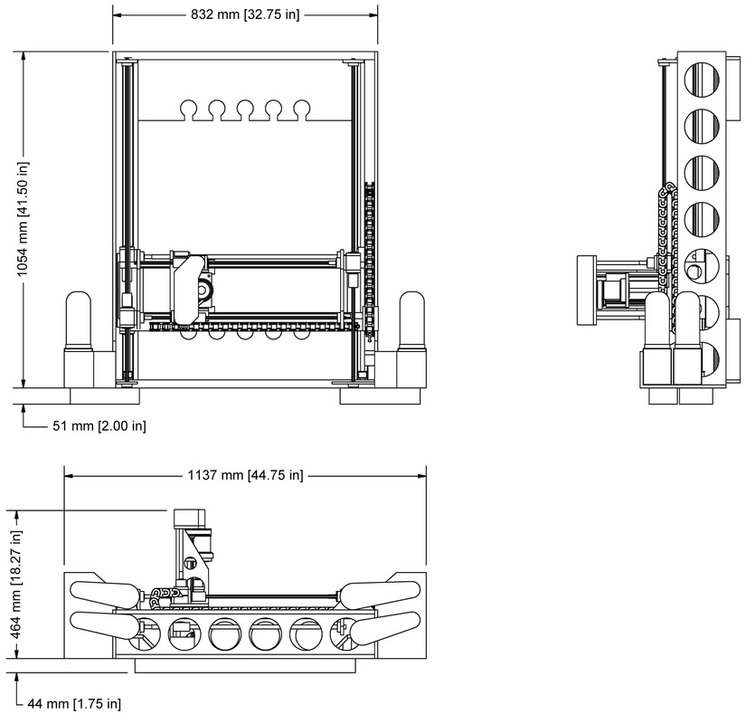

CRM-4 Dimensions